PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

COURSE ID: AED

DURATION: 2 DAYS

Prerequisites: None

The following will be taught and discussed in detail:

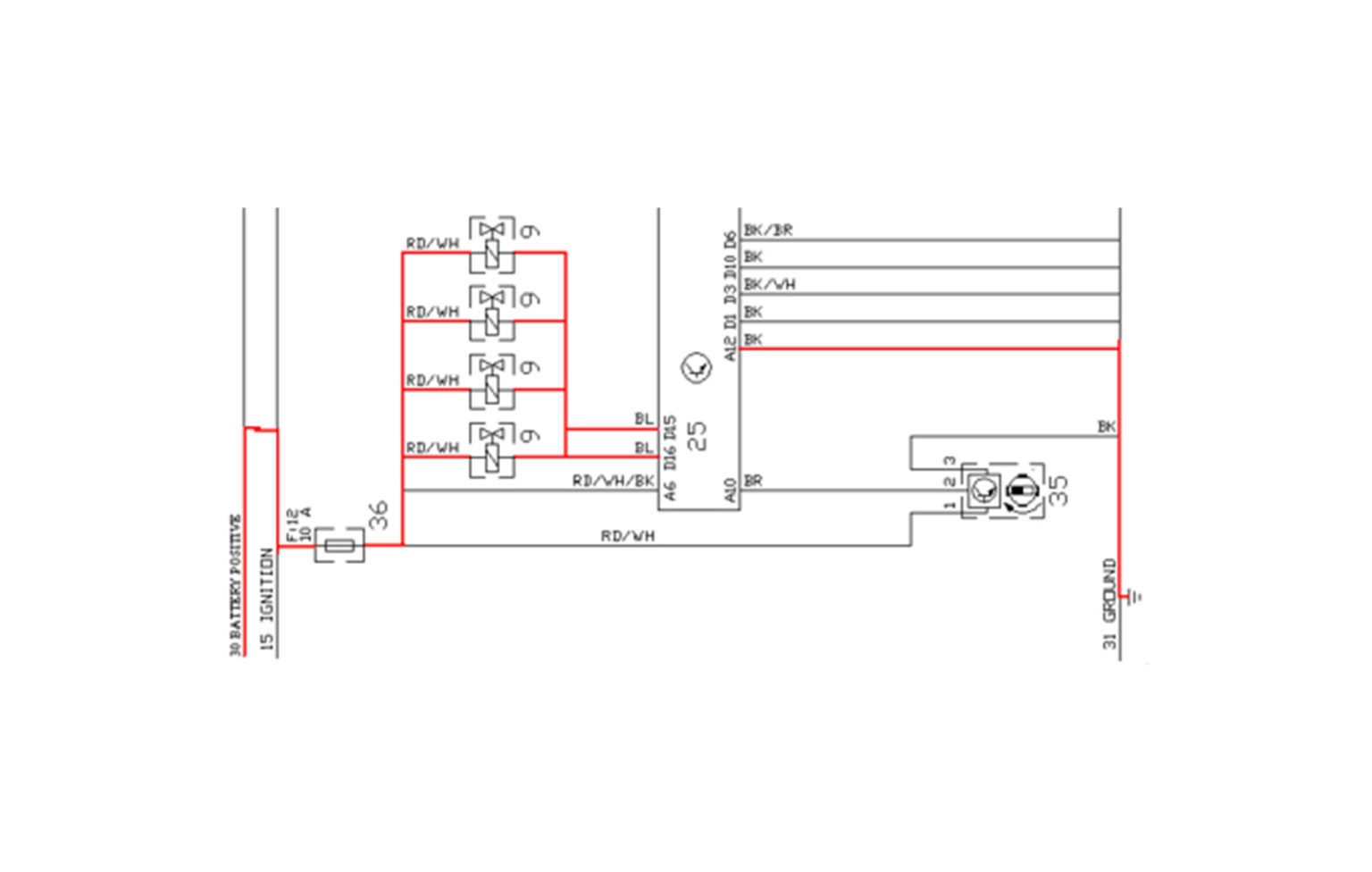

Wiring diagrams

• How to predict signal and supply voltages while reading a wiring diagram before actually measuring and signal and current flow.

• Detect trouble spots and learn how to easily discover bad connections. Understand how poor connections can have a direct effect on adaption values.

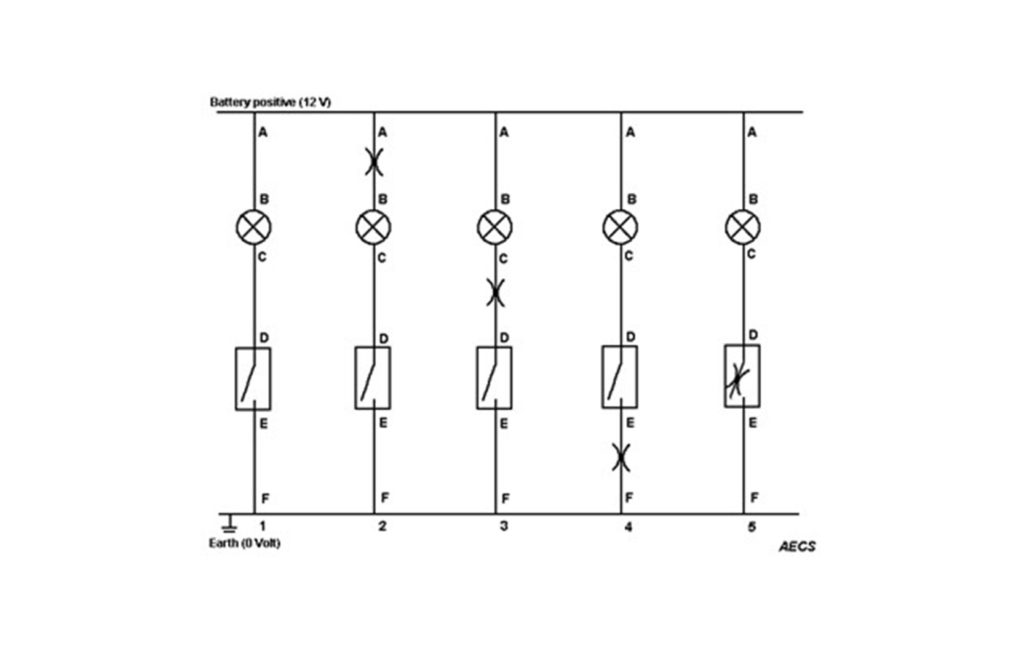

Components Parallel & Series

• Predict voltages in simple wiring diagrams and measure on different types of circuits with regards to diagnostics.

• The effect of failures within a circuit and transistor switched circuits, theory and practical.

Resistors / Resistance Diagnostics

• Effects of poor connections on sensors and actuators, and how they occur.

• How to locate bad connections in actuator and sensor circuits, and the flow-on effect from one faulty circuit that can affect others.

• Poor connections to the ECU and the effect it can cause, we also discuss ECU fault code setting procedure.

Short Circuit Diagnostics

• How to locate different types of short circuits in a sensor circuit with the aid of measurement equipment and fault codes.

• We’ll look at the vehicle engine management system and how short circuit variants (either full short or part short circuits) is affected.

Automotive Variable Resistors

• Carbon track and measuring vane construction and principles.

• How to diagnose faults in variable resistors and dual variable resistor track in drive-by wire systems.

• Fault code setting methods by the ECU and ECU hard and soft trigger values (for understanding generic ECU working principles).

Inductive Sensors

• Coil/core construction of inductive sensors.

• Magnetic field disturbance and signal generation.

• ECU trigger values and fault code setting methods by the ECU.

• Relation between, for example, crank and camshaft sensor signals.

Hall Sensors

• Working principle of hall sensors from a diagnostic perspective.

• Signal diagnostics and ECU trigger values.

• Fault code settings via soft parameters.

• How to diagnose signal with multimeter.

• Latest Toyota Hall sensor variation and fault codes triggers and common faults.

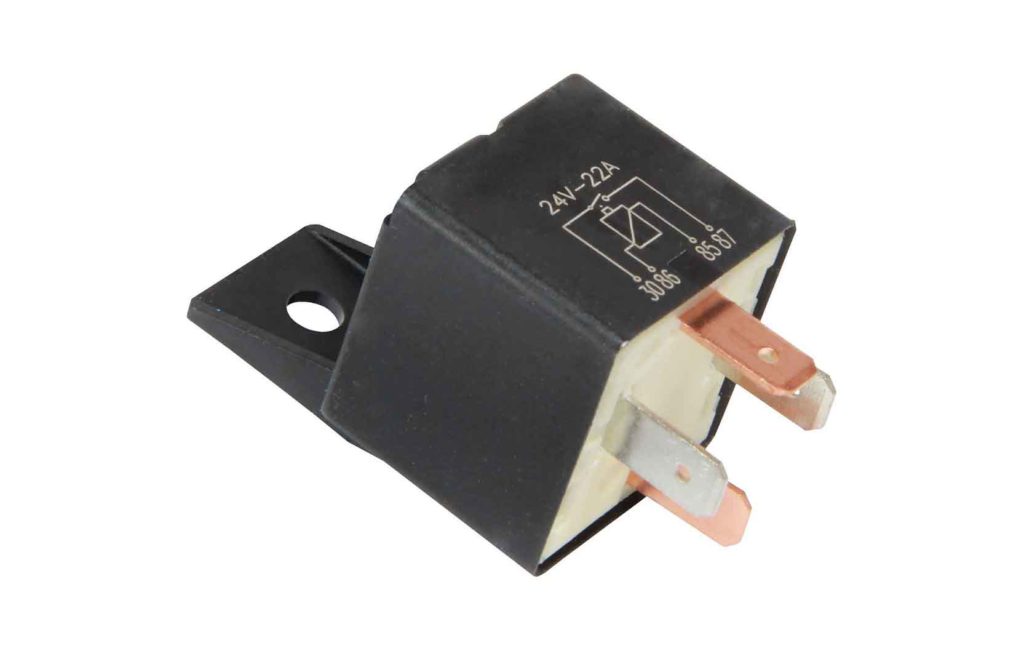

Solenoids and Relays

• Magnetic fields and the effect on cores and needles.

• NO, NC valves and activation and de-activation of coils.

• How induced spikes are generated and where they are affecting the overall electronic system. Protection circuits in relays and the most commonly made connection mistakes with regards to protection circuits.

Temperature Sensors

• Circuit description in and outside the ECU.

• Understanding voltage signal including diagnosing the thermostat without taking it out of its housing.

• Fault code setting methods by the ECU and ECU trigger values.

• The impact of bad connections and shorts, specifically on a modern CAN data bus system.

• Multec temp sensor system description (e.g. Holden).

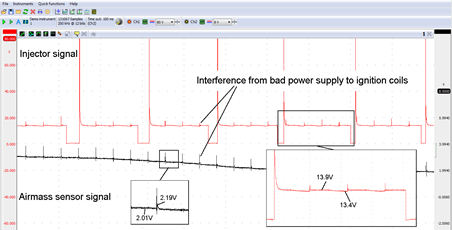

Ignition Modules

• Simple system description and activation including common problems when the ignitor fails as a result of, for example, a removed spark lead.

• Signal voltage description and shortcomings of a multimeter.

• More complex ignitor module description Toyota V6 (ignition feedback) and Holden V6 (ignition control switch over).

• Determining the correct coil replacement parameters.

Multimeter Knowledge

• Using a multimeter correctly and correct measuring practices on electronic systems.

• Shortcomings of multimeters in electronics.

• Why you shouldn’t use Ohms/resistance measurements in most diagnostics.

A short video with content from an actual AED training seminar.

The team at AECS are here to help. Let us know how we can be of assistance.