PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

DED (Diesel Electronic Diagnostic) is designed to give the commercial vehicle or diesel technician a thorough insight into electronic fault diagnostics of diesel vehicles. This seminar makes the increasingly complex onboard vehicle electrical systems simple to understand and easy to diagnose.

The following will be taught and discussed in detail:

Wiring Diagrams

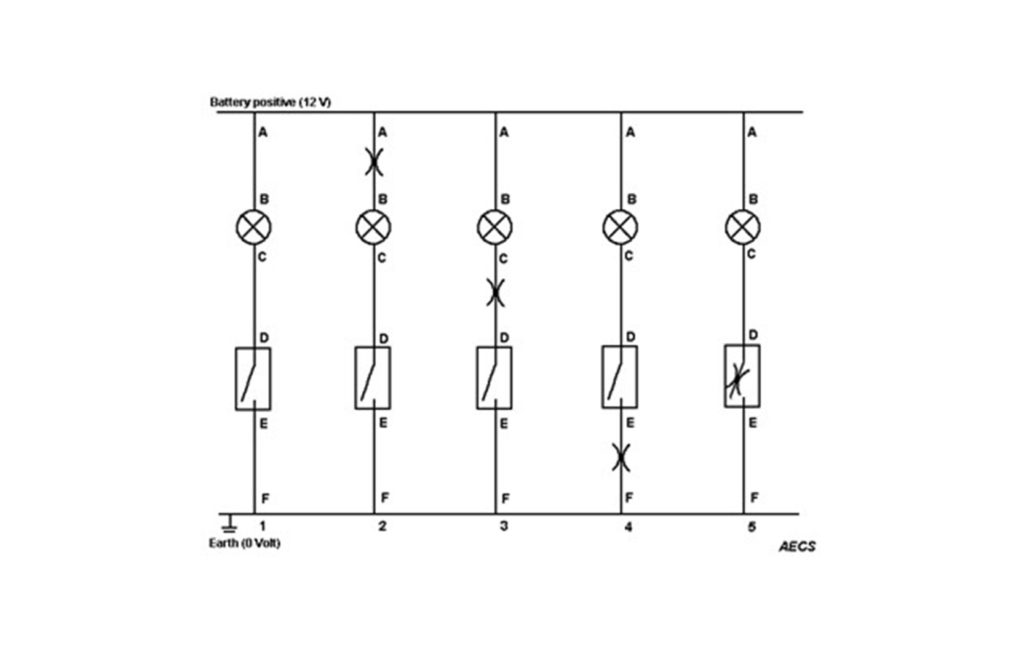

• How to predict signal and supply voltages while reading a wiring diagram before actually measuring and signal and current flow.

• Detect trouble spots and learn how to easily discover bad connections. Understand how poor connections can have a direct effect on adaption values.

Components Parallel & Series

• Predict voltages in simple wiring diagrams and measure on different types of circuits with regards to diagnostics.

• The effect of failures within a circuit and transistor switched circuits, theory and practical.

Resistors / Resistance Diagnostics

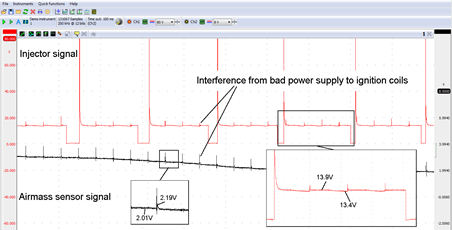

• Effects of poor connections on sensors and actuators, and how they occur.

• How to locate bad connections in actuator and sensor circuits, and the flow-on effect from one faulty circuit that can affect others.

• Poor connections to the ECU and the effect it can cause, we also discuss ECU fault code setting procedure.

Inductive Sensors

• Coil/core construction of inductive sensors.

• Magnetic field disturbance and signal generation.

• ECU trigger values and fault code setting methods by the ECU.

• Relation between, for example, crank and camshaft sensor signals.

Hall Sensors

• Working principle of hall sensors from a diagnostic perspective.

• Signal diagnostics and ECU trigger values.

• Fault code settings via soft parameters.

• How to diagnose signal with multimeter.

• Latest Toyota Hall sensor variation and fault codes triggers and common faults.

Short Circuit Diagnostics

• How to locate different types of short circuits in a sensor circuit with the aid of measurement equipment and fault codes.

• The effect of short circuits variants (either full short or part short circuits) on the engine management system.

Automotive Variable Resistors

• Carbon track and measuring vane construction and principles.

• How to diagnose faults

• Fault code setting methods by the ECU, including ECU hard and soft trigger values (for understanding generic ECU working principles).

• Dual variable resistor track in drive by wire systems.

Solenoids & Relays

• Magnetic fields and the effect on cores and needles.

• NO and NC valves.

• Activation and de-activation of coils.

• How induced spikes are generated and where they are affecting the overall electronic system.

• Protection circuits in relays and the most commonly made connection mistakes with regards to protection circuits.

Multimeter Knowledge

• Proper measuring practices on electronic systems.

• Shortcomings of multimeters in electronics.

• Why you shouldn’t use Ohms/ resistance measurements in most diagnostics.

Temperature Sensors

• Circuit description in and outside the ECU

• Voltage signal understanding includes diagnosing the thermostat without taking it out of its housing.

• Fault code setting methods by the ECU.

• ECU trigger values.

• The impact of bad connections and shorts, specifically on a modern CAN data bus system.

The team at AECS are here to help. Let us know how we can be of assistance.