PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

In Denso Common Rail Systems training, we will teach you about popular common rail diesel engine management systems with an emphasis on Denso. You will learn how to diagnose current faults and prevent and find looming faults. On completion of the two day training, you will understand the interaction of components that will assist in making accurate and efficient diagnostic conclusions.

$764.00 +GST

Prerequisites: It is prefered that you have completed DED or AED, no matter what level of experience or previous training systems.

Equipment: This training is scope based, please bring your own scope or if you don’t have one AECS can provide one for training.

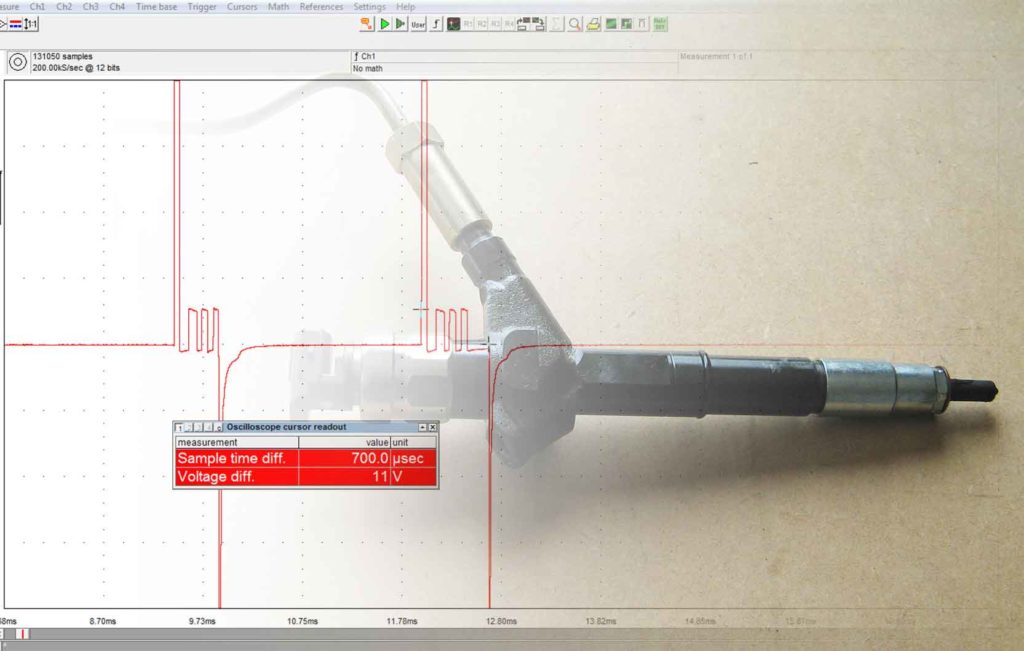

Coiled CR Injectors

In this Denso Common Rail Systems training, we will start with a discussion on coiled CR injectors. Including mechanical construction, response speed, common faults such as a rattly engine and high voltage shot opening.

Injection Timing

We share the importance of injection timing including what sensors affect CR injection timing and how to measure to check if the timing is correct.

Sensors

We look at the signals produced by each sensor in the system, what the signal should look like and examine common faults. We discuss the acceptable level of induced injector interference on each sensor.

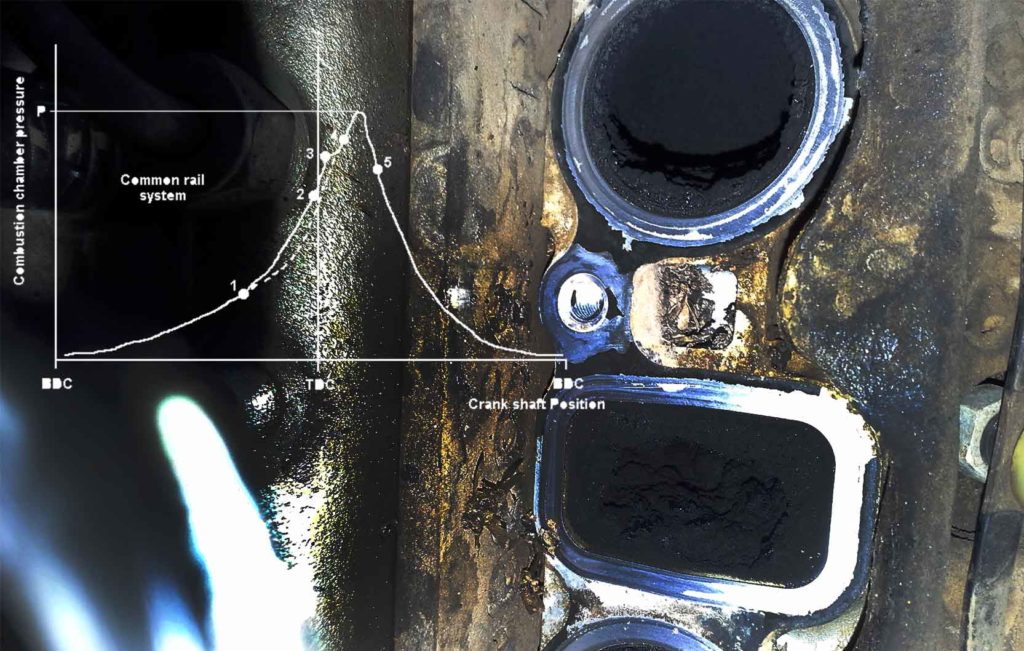

Combustion

The most important part of diagnosing Common Rail Diesel is understanding the combustion process. We will explain in detail why each sensor is an integral part of the system and our workflow as to which sensor to look at first when trouble erupts. This includes piston movement and we’ll share about the pressure graph.

High Voltage & High Current

We will teach you about high voltage and high current. This includes how the high voltage is made in the ECU or the injector driver, how the injector driver is activated and how to test. We discuss the significance of the inclination on a current graph.

SCV/PDV and Rail Pressure.

The suction control valve and pressure discharge valve have a very important role, to diagnose you need to look at the relationship between the valves and rail pressure sensor. We will teach you several different methods to make it instantly visible to determine where a fault is.

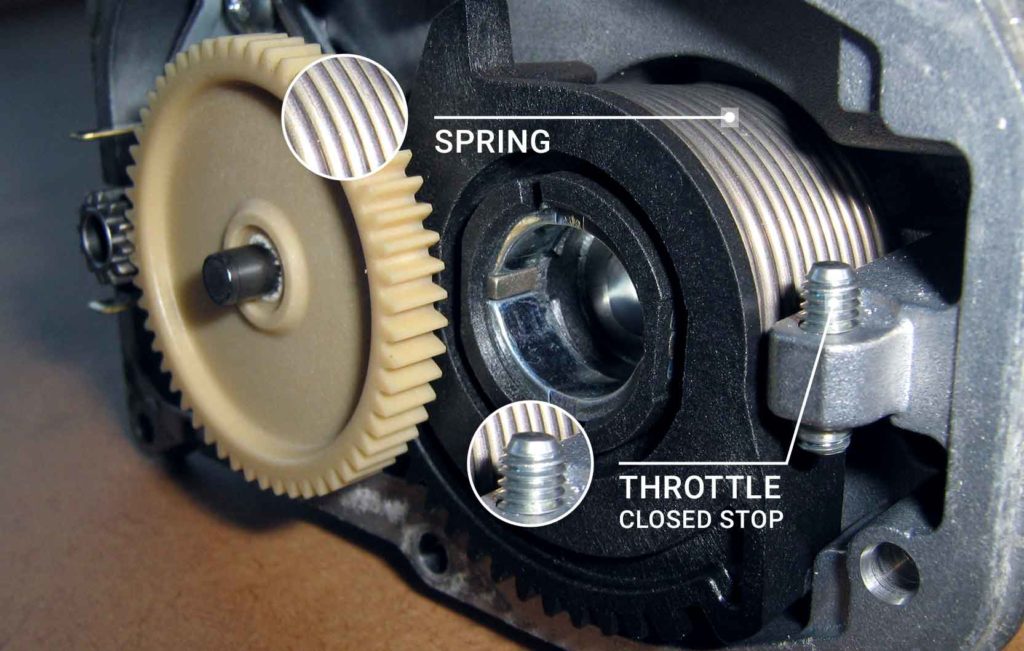

Throttle Body & EGR Control

We look at how the throttle and EGR valve are controlled, why they are there and what are the most common faults. We consider throttle body functions, construction and electric motor diagnostics and throttle body feedback system construction and diagnostics.

Cat & DPF

The whole exhaust system of even the most simple ute is very complex with many items that need maintenance and care. We will discuss what can go wrong and what you can do to correct issues. Within this, we will share about diesel particulate filter system operation and regeneration and emission values, including DPF temperature, ambient pressure and differential pressure sensors.

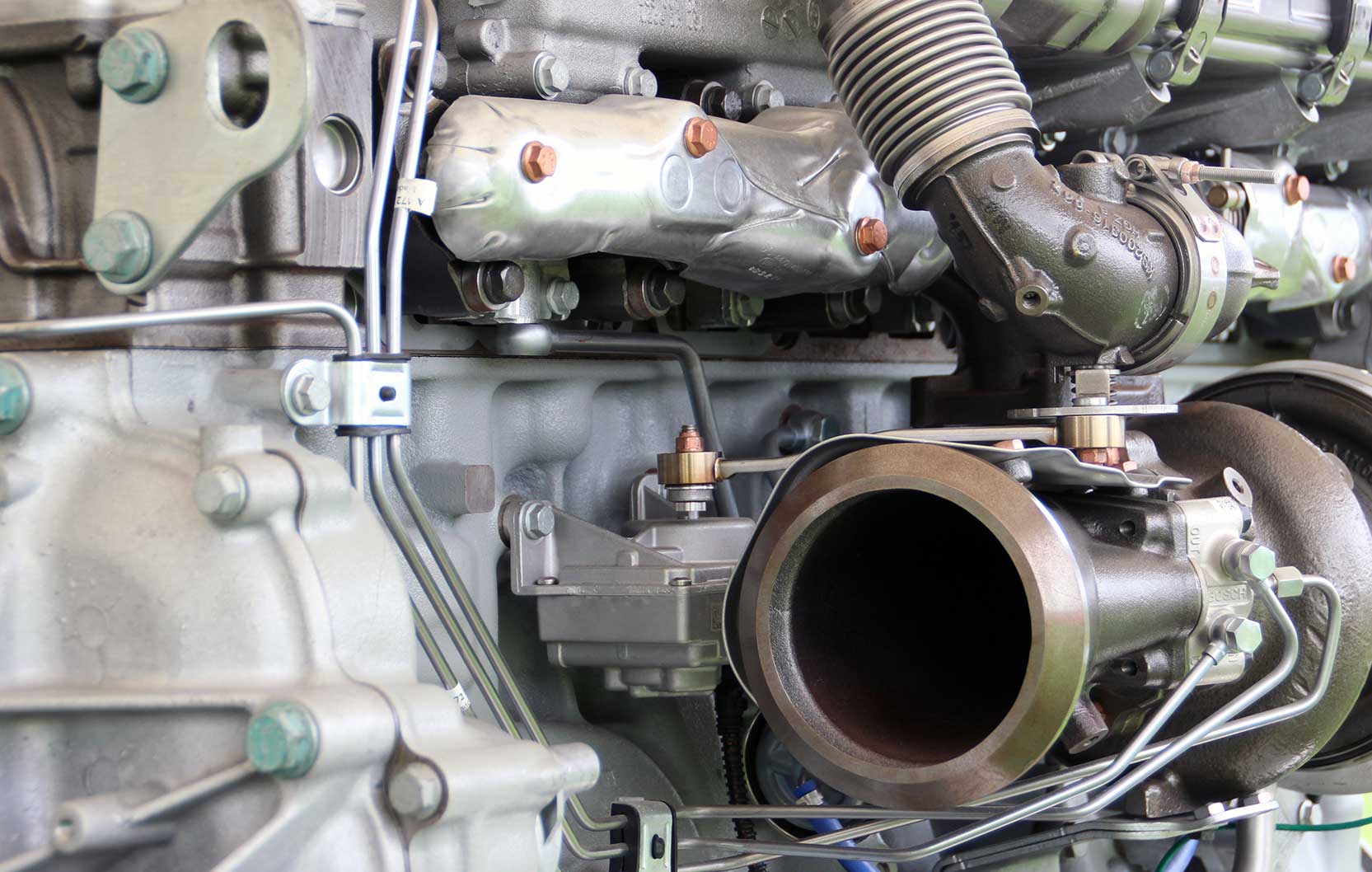

VNT Turbo

Through display models and theory we look at the operation and control of the VNT turbo system, variable nozzle turbo description and fault diagnostics. We look at common faults and how to recognise them with your tools.

Rail Pressure

Lastly, we will look at Rail pressure sensor construction and signal interpretation, using electronic signals to carry out mechanical fault diagnostics on, for example, the injection pump and injectors.

The team at AECS are here to help. Let us know how we can be of assistance.