PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

Vehicle Inspector training is specific training for CoF vehicle inspectors who need an CoF test certificate for NZTA or for technicians who need knowledge on brake roller testers. In this training, we will look at brake science & mechanics and legalities around CoF testing. This is an NZTA approved training.

$399.00 +GST

Please Note: Minimum of 6 trainees apply. Dates subject to training location & schedule. Please call us to discuss – 06 874 9077

Prerequisites: Workshop experience working with or on heavy vehicles.

Getting Started

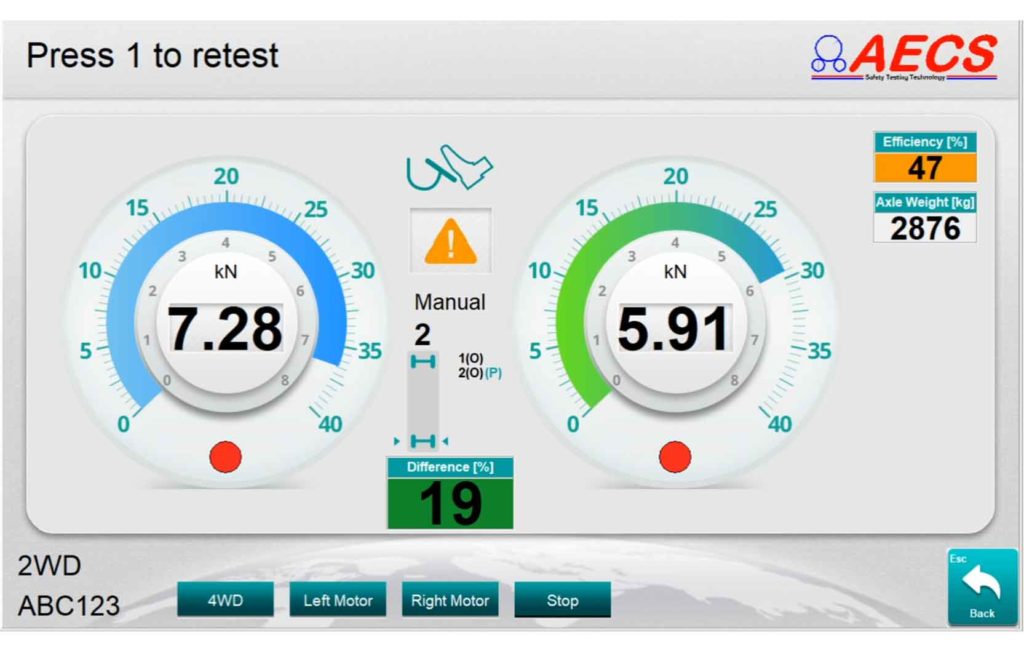

In this training, we will show you how to operate an RBM correctly, step by step. This will include hydraulic lift and pull down, limits, principles and pitfalls. We will look at brake test results interpretation, identification of different HD brake systems and common faults in brake systems. As a vehicle inspector, we will discuss RBM approvals and calibration and what that means for you.

Core Principles

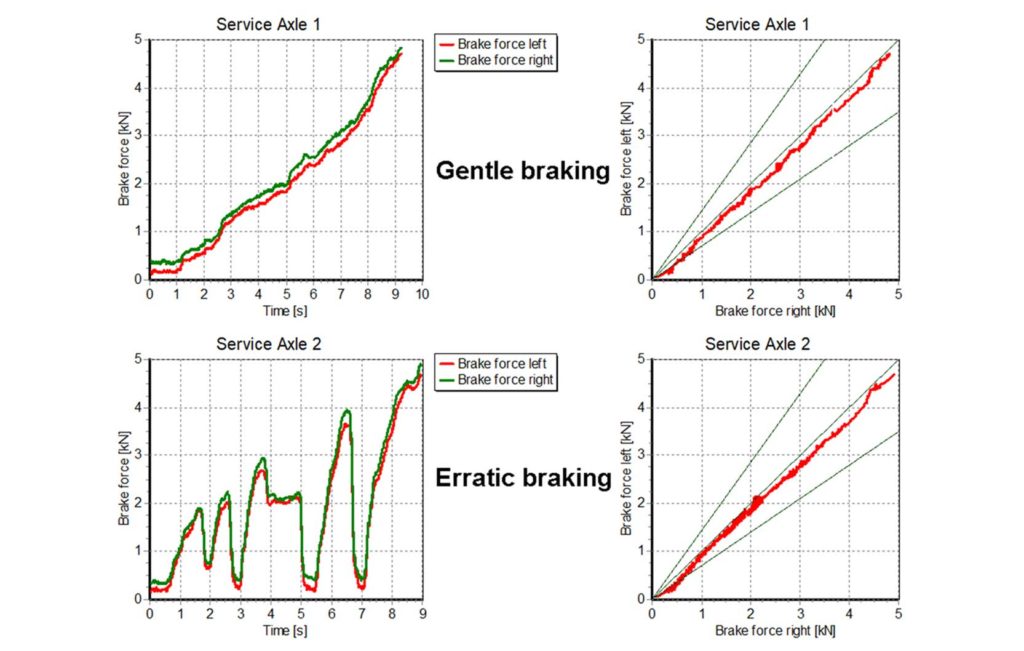

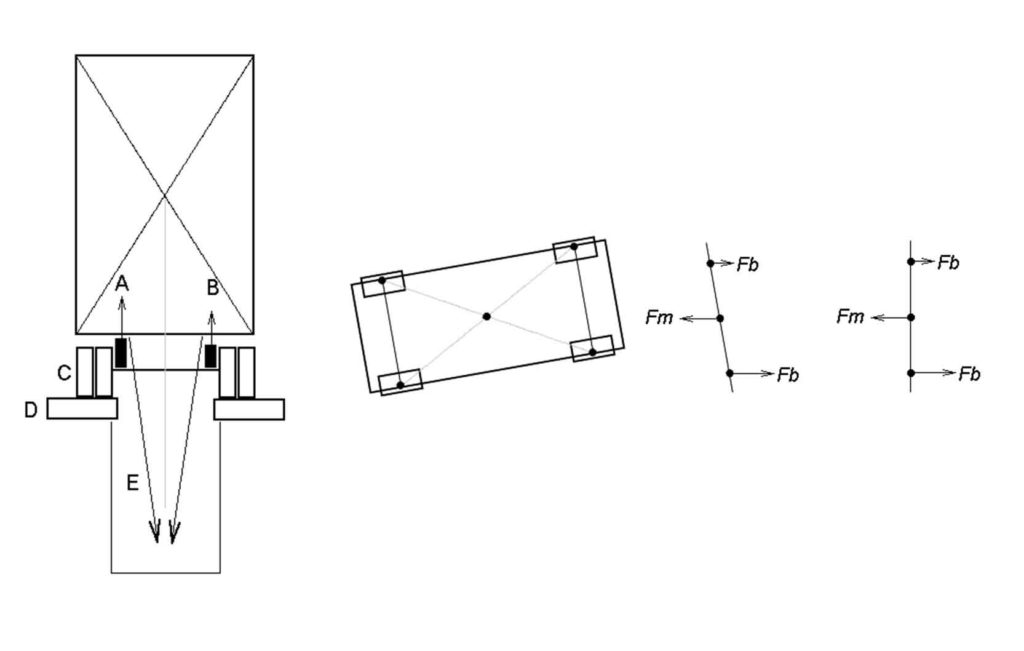

We will help you understand the principles of a roller brake tester, this includes what is measured on an RBM when lock-up occurs and when no lock-up occurs. We will look at what factors affect RBM test results.

Gripped

In simple terms, we’ll teach you about grip and explain the engineering principles behind it, including the effect of weight and grip on measured brakeforce and how this affects the calculated brake efficiency.

Faults

You’ll learn how to predict brake force and efficiency, so you can recognise a vehicle or RBM fault quickly and importantly, we look at how brake efficiency relates to legal minimum deceleration rates.

Surfaces

We’ll show you what happens with brake force when lockup occurs on the road to regain grip (ABS/EBS/ESP), and which factors, for example, roller surface and rubber compound tires etc, affect grip on the road and on the RBM.

Brake Force

We will show you how the RBM measures brake force, why we measure dynamic weight during a brake test and how is it measured. We will also look at the effect of brake imbalance on RBM results and vehicle direction on the road.

Imbalance

We’ll look at factors that affect brake imbalance such as unequal tires, tire pressure and simulated loads. We consider the ins and outs of brake efficiency, plus legal terms and engineering principles.

The team at AECS are here to help. Let us know how we can be of assistance.