PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

PHONE: 06 874 9077 | HOURS: MONDAY-FRIDAY 9AM-5PM

COURSE ID: SCAN 1-1

DURATION: 2 DAYS

Prerequisites: None

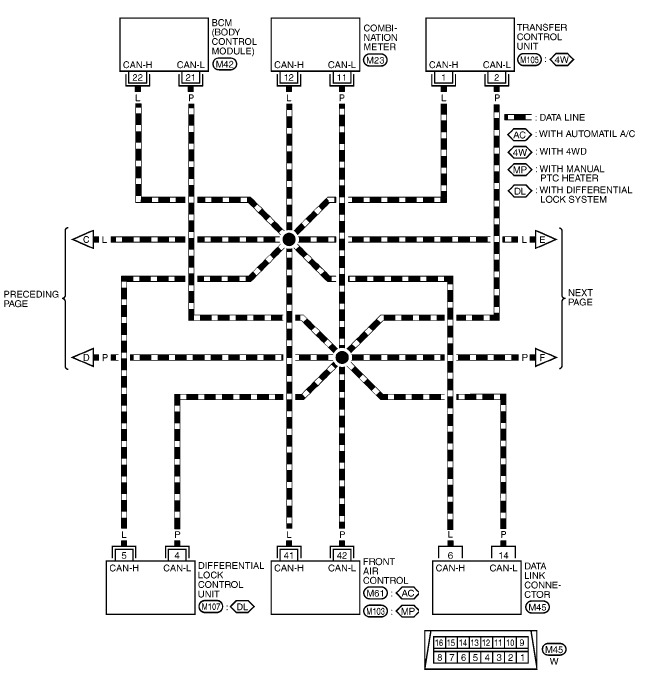

Communication between Scan tool and ECU

How the ECU and scan tool communicate with each other, and what can disrupt communication. What will you as a technician see and notice.

Data flow and exchange

How the ECU and scan tool communicate with each other, and what can disrupt communication. What you as a technician will see from the scan tool.

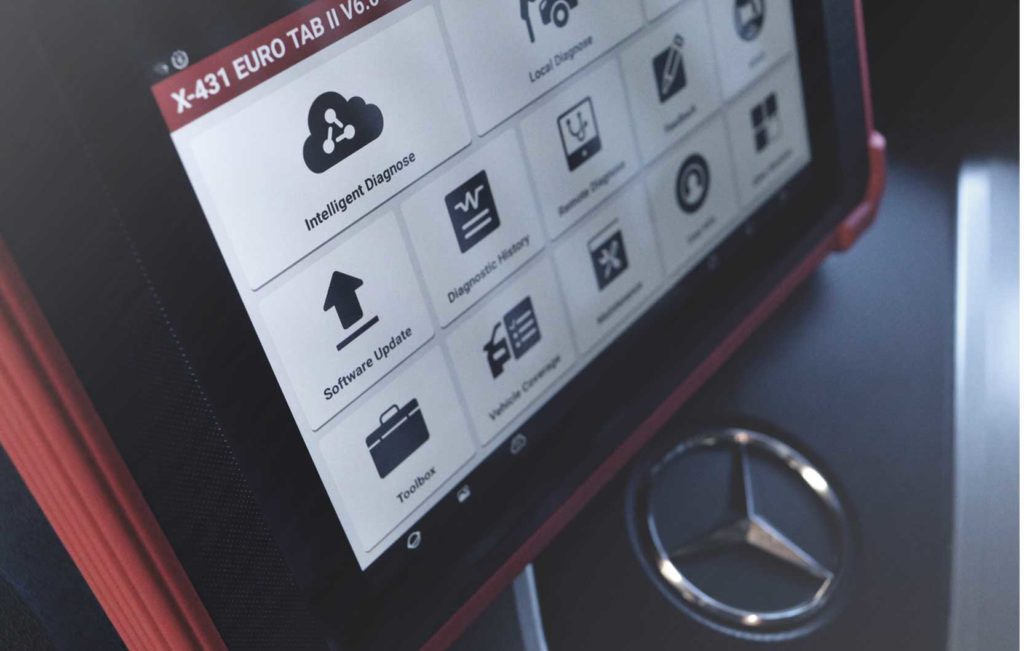

Scan tool configuration comparison

PC based vs handheld vs wired/wireless scan tools. Advantages and disadvantages.

Communication differences

Value of (E-)OBD(2) vs OEM communication. Comparing live data values and lines

Fault codes setting procedures in the ECU

• Direct fault code setting procedure, where a code has a direct relation to the actual fault.

• Indirect fault code setting procedure, where a code is set as a result of a plausibility fault.

• Adaption fault code setting procedure, and diagnostic meanings.

Scan tool library

How to recognise that you have selected an incorrect data conversion table.

Updates

Updating scan tool software, the changes in your tool with new updates and the function of an application list.

Module coding/reflashing

Coding ECU’s in the car and know the difference between coding and flashing. When and why ECUs are reflashed.

Key programming

A simple explanation of how to code a key and how to get started.

The team at AECS are here to help. Let us know how we can be of assistance.